2024 Rail Grinding Machine Industry Analysis

Analysis of the Current Situation of Rail Grinding Machine Industry in 2024: Rail grinding machines are widely used in the high-speed train sector

Introduction

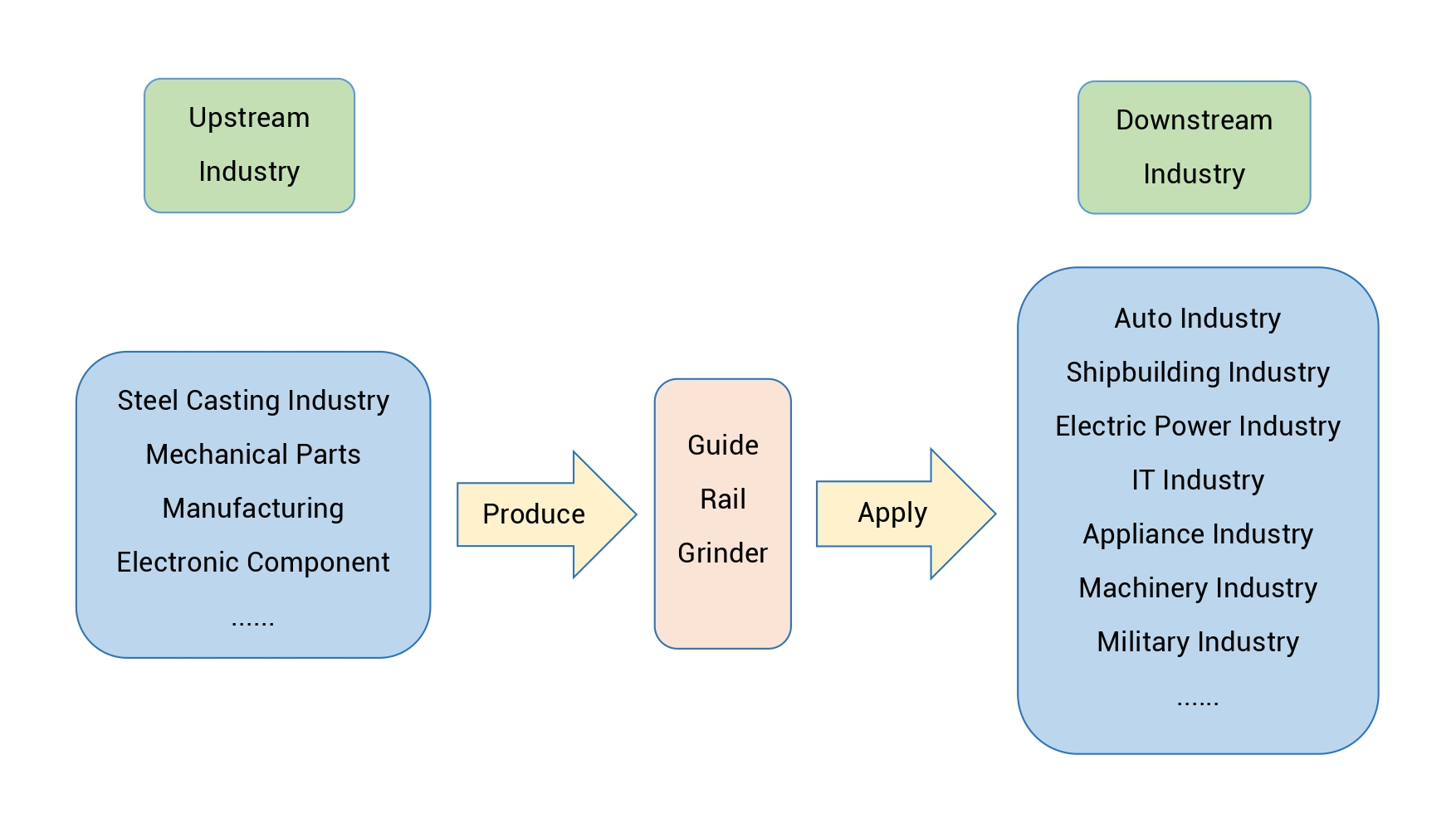

The guide rail grinder, a pivotal equipment within the realm of mechanical processing, boasts widespread application particularly in the domain of high-speed trains. With its origins rooted in the machine tool industry, the guide rail grinder has undergone a significant evolution marked by technological advancements and industrial demands. Initially emerging as a specialized device, it has gradually transitioned from traditional mechanical control methods to automated, digitally controlled systems, enhancing both precision and efficiency in machining processes. Over time, the guide rail grinder has become indispensable in ensuring the precision and smoothness of rails, catering to the escalating requirements of high-speed trains, wind power generation, and aerospace sectors. As the industry continues to progress, the guide rail grinder is poised to further advance towards high precision, efficiency, and intelligence, reflecting a relentless pursuit of excellence in meeting evolving market demands.

History of the Rail Grinding Machine Industry

Initial Stage: Rail grinding machines originated from the machine tool industry, and with the advancement of industrialization, the demand for precision machine tools has been continuously increasing. Rail grinding machines, as specialized equipment, gradually emerged. Initially, rail grinding machines mainly used traditional mechanical control methods, resulting in relatively low production efficiency and machining accuracy.

Technological Improvement Stage: With the development and popularization of CNC (Computer Numerical Control) technology, rail grinding machines gradually realized automation and digital control, leading to a significant improvement in machining accuracy and efficiency. The analysis of the current situation of the rail grinding machine industry indicates that with the continuous progress in materials science, grinding technology, and other fields, the structure and grinding processes of rail grinding machines have also been continuously improved and optimized.

High-end Development Stage: In recent years, with the rapid development of sectors such as high-speed trains, wind power generation, and aerospace, the requirements for rail precision and surface smoothness have become increasingly stringent. The rail grinding machine industry continues to introduce advanced technologies and equipment to enhance product quality and production efficiency, gradually moving towards high-end development.

Current Situation of the Rail Grinding Machine Industry

Market Size: Rail grinding machines, as one of the key equipment in the mechanical processing field, have a large market size. With the advancement of industrialization and the development of the transportation sector, the demand for high-precision rails continues to grow, providing broad market space for the rail grinding machine industry.

Industry Competition: The competition in the rail grinding machine industry is fierce, with numerous manufacturers in the market and a significant phenomenon of product homogeneity. The analysis of the current situation of the rail grinding machine industry points out that companies need to engage in differentiated competition through technological innovation, brand building, service quality, etc., to seek breakthroughs.

Development Trends: In the future, the rail grinding machine industry will continue to develop towards high precision, high efficiency, and intelligence. With the digital transformation and trend towards intelligence in the manufacturing industry, rail grinding machine products will pay more attention to intelligence and automation to meet market demands.

Prospects of the Rail Grinding Machine Industry

Market Demand Growth: With the continuous development of transportation, machinery manufacturing, and other industries, the demand for high-precision rails keeps increasing. Particularly in fields such as high-speed trains and high-end machine tools, the requirements for rail precision are becoming higher, which will drive the demand growth for rail grinding machines.

Technological Upgrades: With the continuous advancement of technology, the rail grinding machine industry is also undergoing continuous technological innovation and upgrades. The analysis of the current situation of the rail grinding machine industry indicates that the application of digitalization, intelligence, automation, and other technologies will enhance the machining accuracy, efficiency, and stability of rail grinding machines to meet the market's demand for high-quality rails.

Government Support: China's manufacturing industry is implementing strategies like "Made in China 2025" to increase support for high-end equipment manufacturing. As an important component of high-end equipment, rail grinding machines will benefit from related policy support, aiming to achieve greater breakthroughs in technological levels and market positions.

International Market Expansion: Chinese rail grinding machine products have a certain competitiveness in the international market, with export volumes gradually increasing. With the advancement of the "Belt and Road" initiative, Chinese companies are expected to further expand overseas markets and enhance international competitiveness.

Overall, the rail grinding machine industry has broad market prospects and development opportunities, but it also needs to face fierce market competition and technological challenges. Companies need to continuously improve their technical capabilities, strengthen innovation, and adapt to market changes to establish a dominant position in the industry.